Save time and cost with Universal Plastics' Value Added Services.

Universal Plastics offers many in-line extrusion operations as well as off-line secondary operations.

PLASTIC EXTRUSION

CAPABILITIES

Please contact us concerning your special plastic extrusion production needs.

Our application engineers are ready and available to answer your questions and assist you with your projects.

We can manufacture these types of extrusions:

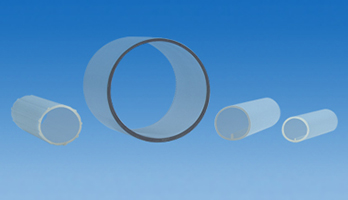

Tubing

Universal Plastics manufactures flexible and rigid plastic extruded tubing products and plastic profiles for diverse industries.

More Information

Cores

We manufacture plastic cores for various industries, including fishing, paper, tape, yarn, medical and fabric. Our plastic cores provide reinforcement for larger spools and are clean, dust-free, and dimensionally stable.

More Information

Rods

Universal Plastic manufactures

flexible and rigid custom plastic

extruded rods from .035" to .50"

diameter sizes.

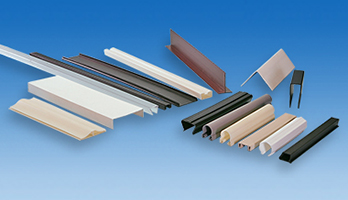

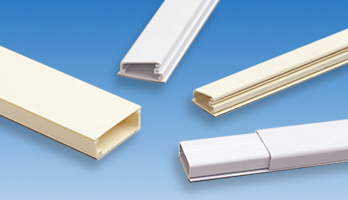

Profiles

Universal Plastics manufactures plastic profile extrusion shapes in almost every configuration possible, from simple U-shaped channels to complex hollow profiles. Plastic extrusion profiles are our area of expertise.

More Information

Co-Extrusions

Co-extruded plastic profiles combine and bond two or more different plastic materials into a one-piece product. The combined materials can be rigid and flexible, different colors, and different additive mixes.

More InformationTHE UNIVERSAL PLASTICS

EXTRUSION ADVANTAGE

Our core competency is in

custom extrusion services:

- 24 hour in-line extrusion operations

- Extrusion lines up to 3" for tubing outer diameter and 6" wide for profiles

- Wide variety of extrusion plastic materials

- Professional plastic extruder operators

We have experience extruding

with these materials:

- ABS (Acrylonitrile Butadiene Styrene) Elastomers

- Flexible Polyvinyl Chloride (PVC)

- Polyolefins

- Polystyrenes

- Polyurethanes

- Rigid Polyvinyl Chloride (PVC)

- Thermoplastic Elastomers

Why choose Universal Plastics

for your extrusion needs:

- Minimize tooling costs

- Utilize custom polymers

- Speed tooling to sample

- ISO 9001:2015 Certified Quality Management System

- Manage inventory with Just-In-Time-Delivery, Lean Manufacturing, Blanket Orders and Kanban Systems

- In-house machining

- Custom color matching

- Outstanding customer service

and innovation

Materials available that are

green and sustainable:

- Post-consumer and post-industrial materials

- Biodegradable and antimicrobial

- Non-brominated RoHS compliant

flame retardant

Value Added Services:

Universal Plastics is here to save you time and money with custom cutting, light assembly, printing and custom packaging. Let our 30 years of experience go to work for you with design and engineering process assistance for your extrusion profile project.