Universal Plastics provides plastic injection molding for domestic and international customers in a variety of industries. High quality and on-time delivery are our standard benefits.

We have customers in the food and beverage, containers, packaging, sporting goods, and medical devices.

INJECTION MOLDED PARTS

Plastic molding is a manufacturing process for injecting molten plastic material into a mold. Plastic injection molded parts can be made from a variety of plastics.

We have many options for injection mold types based on expected demand volume.

Injection molding is an excellent process for making high volume plastic parts with simple or even complex geometries. Universal molds are precision-machined from steel or aluminum. Engineering design will consider plastic material shrinkage rates so that the mold is constructed to compensate. The manufactured part will match the CAD model specifications.

HOW IT WORKS

The Method

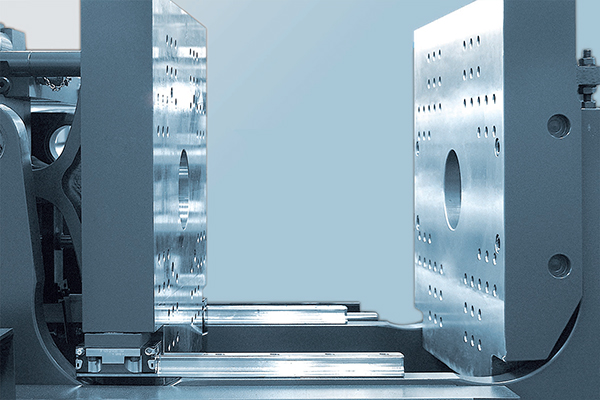

Injection molding is a manufacturing process which produces parts by injecting melted plastic into a mold. Molds are typically 2 pieces of metal which are pressed together to hold the shape until the material has cooled. The material flows into a barrel and pushed into the mold cavity. The shot time is the amount of time it takes for the part to cool and harden to the design specification. Then the mold halves separate and ejector pins may be used to push the part out of the mold where it falls into a bin. Then the mold halves close and the process begins again for the next part.

Equipment

The mold or die refers to the tooling used to produce plastic parts in injection molding. Traditionally injection molds have been costly to make and were used only in high-volume applications.

Value Added Services

Universal Plastics can save you time and reduce costs with our additional services of private labeling/printing, light assembly and custom packaging. Twenty-four-hour-a-day production and a large warehouse of raw materials help us to ensure that your injected molded plastic products and parts are delivered on schedule.