Universal Plastics is one of the few plastic extrusion and injection molding companies that emphasizes the importance of Lean Manufacturing methods.

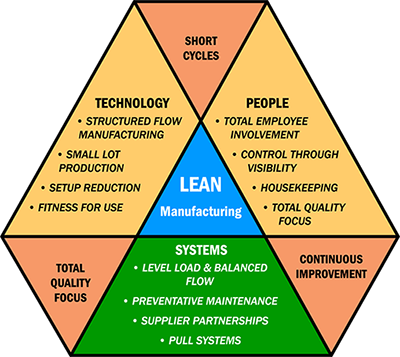

LEAN MANUFACTURING

- Improved customer service: We deliver exactly what you want, when you want it.

- Improved productivity: Enhancements in output and value.

- Quality: Reductions in imperfections and modifications.

- Innovation: We are committed to improved team member morale and contribution to the business.

- Reduced Waste: Less moving, transportation, waiting, space and physical waste.

- Improved Lead Times: We are able to respond more quickly, set up quicker, and encounter fewer delays.

- Improved Stock Turns: Less work in progress and inventory, so less capital tied up.

- Kanban: a visual system to support flow of product through the manufacturing process to support your objectives.

- 5S: a visual maintenance technique which puts control in the hands of the people actually producing your products.

- Visual Control: a system owned by the production team which helps us to visually measure performance in production so that our customers’ products are manufactured efficiently and correctly every time.